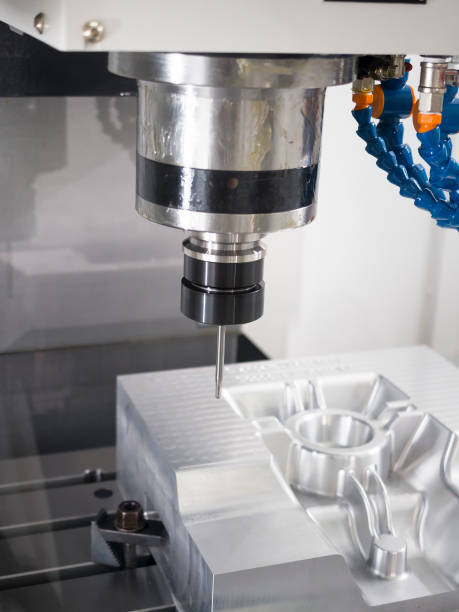

CNC MACHINED PARTS

CNC Turning

3D FUSION employs advanced machines with live tooling and automatic bar feeders, allowing us to perform some tasks without the need for additional setups. The turning process can produce complex external and internal geometrieswith very tight tolerances and excellent surface finishes. CNC turning is a more efficient method for any round shaped component, such as shafts, worms, and spheres, and is suitable for rapid prototype low-volume production.

Features of CNC Machining

- Flexible, Versatile, Easily customized

- Highly accurate with tight tolerances

- Lower cost for fixed tooling and preparation

- Suitable for a variaty of materials (aluminum, brass, mild and stainless steels, magnesium and titanium, engineering-grade plastic resins etc.)

- CNC machined components are full strength and can be used soon after processed

CNC Machining Materials

Metal: Steel, Aluminum(6061-T6, 7075), Stainless Steel (17-4, Inconel 625 & 718), Titanium, Magnesium, Zinc, Brass, Bronze, Copper. Learn More

Plastic: POM,Nylon,ABS,PEEK,PTFE,PC,HDPE,PVC,PMMA,PET,PP Learn More

Some important characteristics of the most popular machining materials include:

| Aluminum 6061-T6 |

Aluminum 6061-T6 6061 offers excellent machinability, low cost, and versatility. Wall Thickness:0.75 mm

Tolerances:0.125mm(0.005")

Max part size:200 * 80 * 100 cm

|

| ABS |

| ABS offers high impact strength, low heat conductivity, and low coefficient of friction. |

| PEEK |

| PEEK offers high abrasion and wear resistance, low moisture absorption, and low coefficient of friction. |

| Aluminum 7075 |

| Aluminum 7075 offers high strength, hardness, low weight, and heat tolerance. |

| Acetal |

| This material provides high mechanical strength, superior dimensional stability, and low moisture absorption. |

| Ultem (PEI) |

| Ultem (PEI) is a high-dielectric-strength material with great strength, stiffness, and chemical resistance. |

Examples of material:

CNC Machining Surface Finishes

We provide complete surface finishing options for precision machined parts, such as Anodizing,Bead Blasting,Powder Coating,Electroplating,Polishing,Brushing.

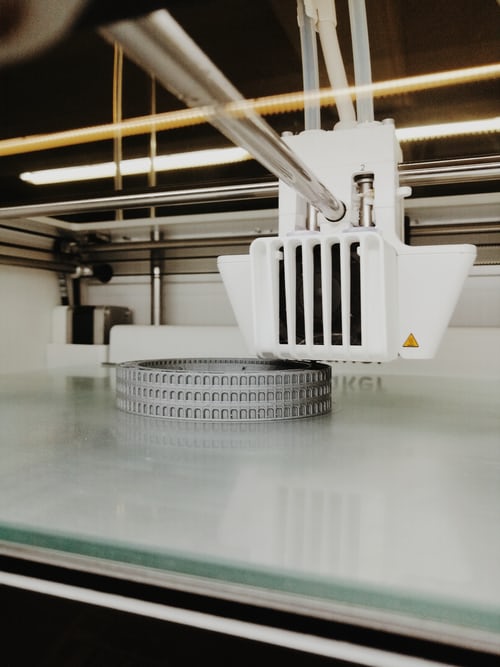

Advantages of 3D Printing

Anodizing

It is typically used on machined aluminum parts to reduce corrosion and add an appealing metallic coloring. Anodizing is a scratch-resistant coating that is both a natural electrical insulator and one of the most durable finishes.

Materials: aluminum, magnesium, titanium.

Texture: Smooth, matte finish.

Thickness: 1.8m to 25m(0.00007")

Type I : Basic type, using chromic acid to produce a thin and ductile anodized layer on an aluminum part

Type II : Utilizes sulfuric acid to produce a thicker anodized layer on a part, making it for a variety of visual effects

Type III: Known as "hard anodizing". Also uses sulfuric acid, but produces a thicker anodized layer, is for surfaces that need to be extra hard

Chemical Film / Alodine: Entails coating part with alodine to produce results that are comparable to anodization

Bead Blasting

Bead blasted parts have a smooth surface with a matte texture.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Texture: Matte

Standards: Sa1, Sa2, Sa2.5, Sa3

Electroplating

Electroplate a single metal or a combination of metals onto parts to increas strength, lifespan, and conductivity of parts.

Materials: Aluminum, Steel, Stainless Steel

Plate type: Zinc, Nickel, Electroless Nickel

Texture: Smooth, glossy finish

Powder Coating

On the surface of parts, powder coating creates a long-lasting, wear-resistant, and corrosion-resistant layer. Powder coating can be used to colour items and is suitable for usage on any metal. Materials: Aluminum, Stainless Steel, Steel Texture: Gloss or semi-gloss

Brushing

Used on metals where a series of tiny parallel lines are scratched onto the surface with a wire brush or polishing tool Materials: ABS, Aluminum, Brass, Stainless Steel, Steel Texture: satin Standards: Sa1, Sa2, Sa2.5, Sa3

Polishing

Get smooth surface by removing cutting marks or printing marks. It is prepare your parts for later painting and plating. For a variety of metallic effects, we can provide brushed and satin surfaces, as well as optically clear polishes on transparent acrylics.

Materials : Aluminum, Brass, Stainless Steel, Steel

Texture: Glossy

Types: Mechanical polishing, chemical polishing